HS85178-HR heat exchanger gasket

Categorie:

Tags:

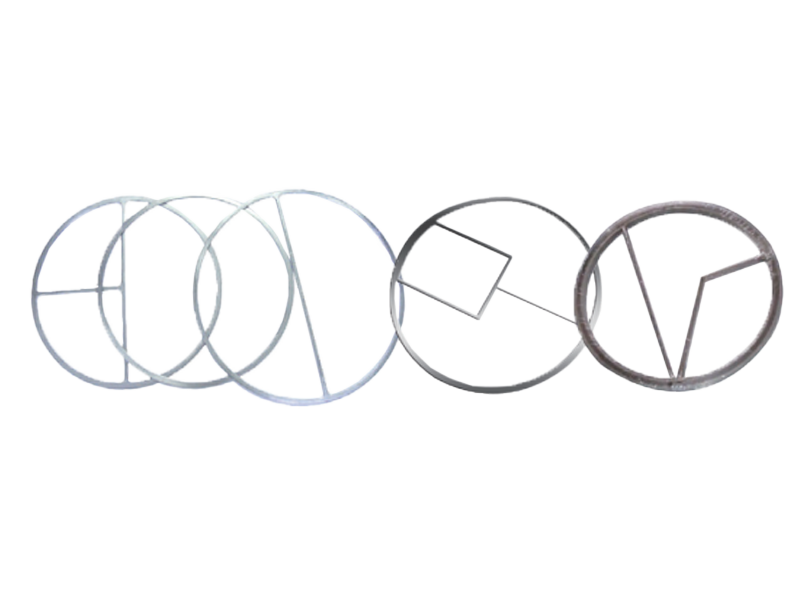

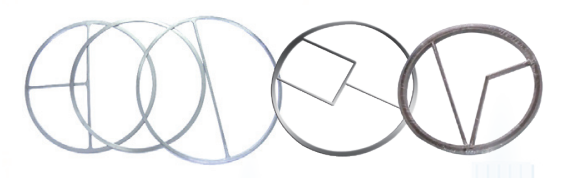

Heat exchanger gaskets are generally divided into tube heat exchanger gaskets and plate heat exchanger gaskets, the main role is to ensure that the heat exchanger in the heat exchange process of sealing, so as to ensure that the heat in industrial production from the higher temperature of the fluid to the lower temperature of the fluid temperature to meet the process requirements of the process to meet the needs of the process conditions. Heat exchanger gaskets are widely used in petroleum, chemical, electric power, metallurgy, shipbuilding, machinery, HVAC, food, pharmaceutical, aviation, environmental protection, urban heating and other industrial fields. Tubular heat exchanger gaskets are generally divided into tube box gaskets, floating head gaskets, tube box side gaskets, outer head cover gaskets and head cover gaskets. There are different gasket forms according to different tube passes. For multi-tube passes, different forms of ribs are generally required on the inner ring of the gasket (attached figure). Commonly used shell and tube heat exchanger gaskets are oil-resistant asbestos rubber gaskets, non-asbestos gaskets, graphite composite gaskets, metal wound gaskets, metal sheathing gaskets, metal tooth composite gaskets and so on. Plate heat exchanger gasket is a key part of the heat exchanger. As the application field of plate heat exchangers continues to expand, there are different requirements for temperature resistance, pressure resistance and corrosion resistance for different media and processes. The working temperature of the plate heat exchanger is actually the temperature that the sealing gasket can withstand. However, gaskets of different materials should be used according to different situations. The commonly used gasket materials include fluorine rubber, tetrapropylene fluorine rubber, EPDM, nitrile rubber, etc. The commonly used gasket cross-sectional shape is hexagonal. Plate heat exchanger gasket according to the installation method on the heat exchanger plate, can be divided into three forms: direct paste type, glue nail inlay type, buckle type.

|

|

| Type | Tube Heat Exchanger Gasket HS85178-HRG |

|

|

| Type | Plate Heat Exchanger Gasket HS85178-HRB |

Product Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend Products