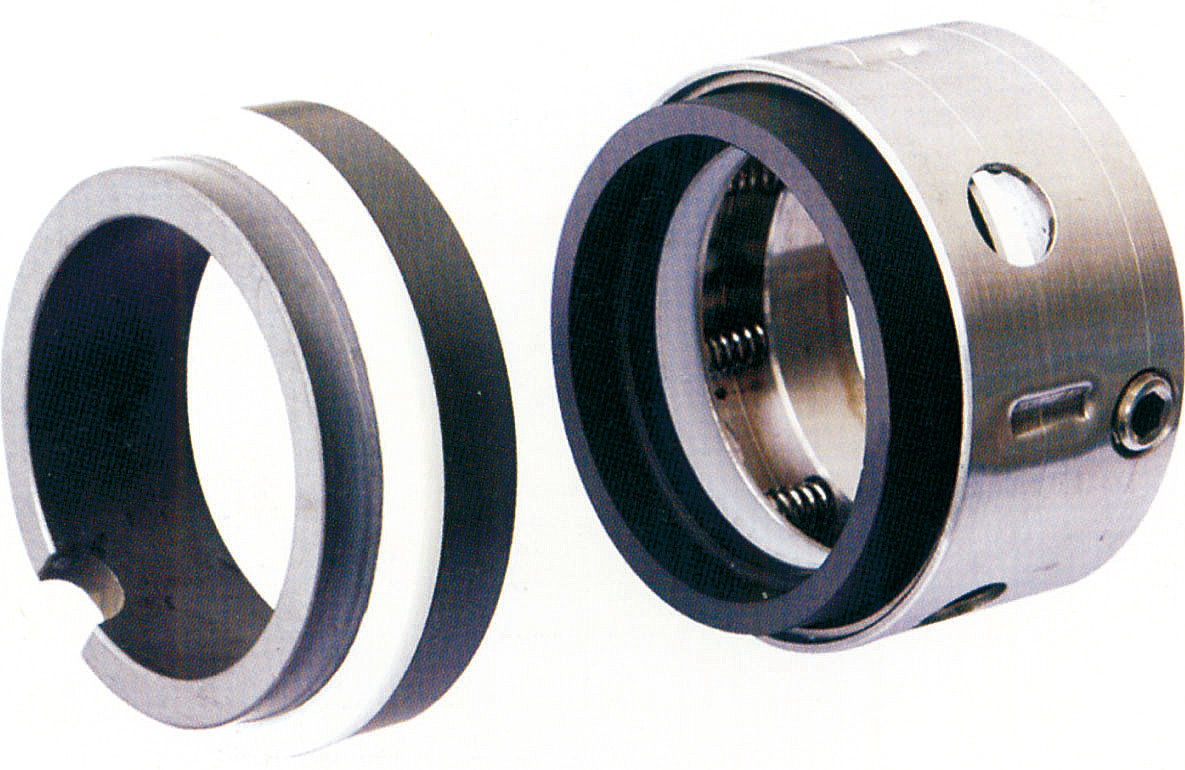

59U mechanical seal

Categorie:

Tags:

This series of mechanical seals are multi-spring structure, small axial size, compact structure, reliable sealing, widely used in oil, water, organic solvents and other corrosive media.

Prev:

:Next

|

Type 108U mechanical seal |

152WB2 mechanical seal |

BIA type mechanical seal |

|

|

|

|

| Seal introduction: water, oil, medium corrosive liquid and medium containing solid particles Sealing chamber pressure: ≤ 0.6Mpa Speed: ≤ 3000r/min (line speed: ≤ 20m/Sec) Sealing chamber temperature: 0 ℃- 180 ℃ (fluorine rubber) -20 ℃ ~ 90 ℃ (nitrile rubber) -30 ℃- 120 ℃ (EPDM) -40 ℃ ~ 230 ℃ (PTFE) -40 ℃ ~ 230 ℃ (PTFE rubber) |

Single-end/balanced/arbitrary rotation/PTFE bellows This series is a tetrafluoroethylene bellows type, which adopts a multi-spring structure, in which the VB2 type spring is protected by a PTFE cover. This type of seal is one of the most widely used in corrosion-resistant pumps. |

Single-end/unbalanced/arbitrary rotation/rubber bellows Sealing chamber pressure: ≤ 0.6Mpa Sealing chamber temperature:-20 ℃ ~ 150 ℃ Line speed: ≤ 10m/Sec Sealed medium: water, oil, weak corrosive medium, cheap, widely used. Static and Dynamic Ring Material: Resin Impregnated (Metal) Graphite Silicon Carbide Alumina Cemented Carbide |

| 59U mechanical seal | 1527/1528 mechanical seal | 169 mechanical seal |

|

|

|

|

| Single-end/unbalanced/arbitrary rotation This series of mechanical seals are multi-spring structure, small axial size, compact structure, reliable sealing, widely used in oil, water, organic solvents and other corrosive media. Specification: 14-100mm pressure: ≤ 1.7Mpa Temperature:-20 ℃ ~ 200 ℃ Linear speed: ≤ 25 m/s Axial channeling: ± 0.5mm Seal end face: graphite, silicon carbide, tungsten carbide, alumina Auxiliary seal: nitrile rubber, fluorine rubber, propylene rubber, PTFE |

1528 type mechanical seal is a derivative of 1527 type mechanical seal. Its installation size is the same as 1527 type, but 1528 type sealing ring has various forms, such as PTFE V-ring, PTFE O-ring, etc. It is more widely used. Sealing cavity pressure: ≤ 1.0MPa Sealing chamber temperature:-40 ℃ ~ 180 ℃ Line speed: ≤ 15m/sec Sealed medium: water, oil, weak acid weak alkali and other general corrosive chemical medium. |

Exterior single-end multi-spring PTFE bellows structure. Both dynamic and static rings are made of corrosion-resistant hard alloy or silicon carbide Sealing chamber pressure: 0.5Mpa Sealing chamber temperature:-10 ℃ ~ 150 ℃ Line speed: ≤ 3000r/min Medium: strong corrosive properties such as crystalline alkali salt solution. |

Product Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend Products