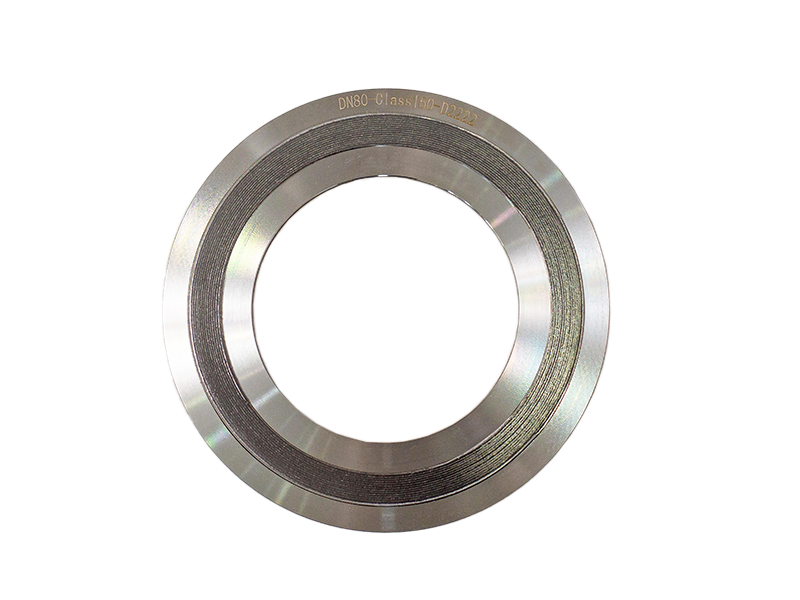

HS8512 Graphite Metal Wrap Gasket D

Categorie:

Tags:

HS8512 graphite metal winding pad is alternately wound with thin steel strip and flexible graphite strip. Its structural density can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. It has the advantages of good resilience, high temperature resistance, corrosion resistance, low leakage rate, etc. In the gasket category, its use temperature is higher. Especially suitable for uneven load, easy relaxation of joint force, temperature and pressure changes periodically, impact or vibration occasions. Valves, pumps, heat exchangers, towers, manholes, hand holes and other flange joint static sealing components. Widely used in petrochemical, machinery, electric power, metallurgy, shipbuilding, medicine, atomic energy and aerospace and other fields.

Product Introduction

HS8512 graphite metal winding pad is alternately wound with thin steel strip and flexible graphite strip. Its structural density can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. It has the advantages of good resilience, high temperature resistance, corrosion resistance, low leakage rate, etc. In the gasket category, its use temperature is higher. Especially suitable for uneven load, easy relaxation of joint force, temperature and pressure changes periodically, impact or vibration occasions. Valves, pumps, heat exchangers, towers, manholes, hand holes and other flange joint static sealing components. Widely used in petrochemical, machinery, electric power, metallurgy, shipbuilding, medicine, atomic energy and aerospace and other fields.

D |

|

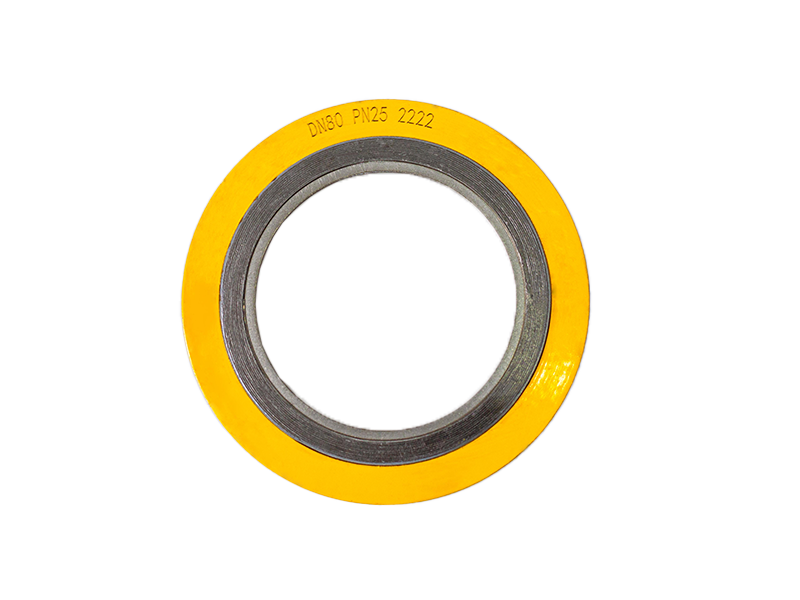

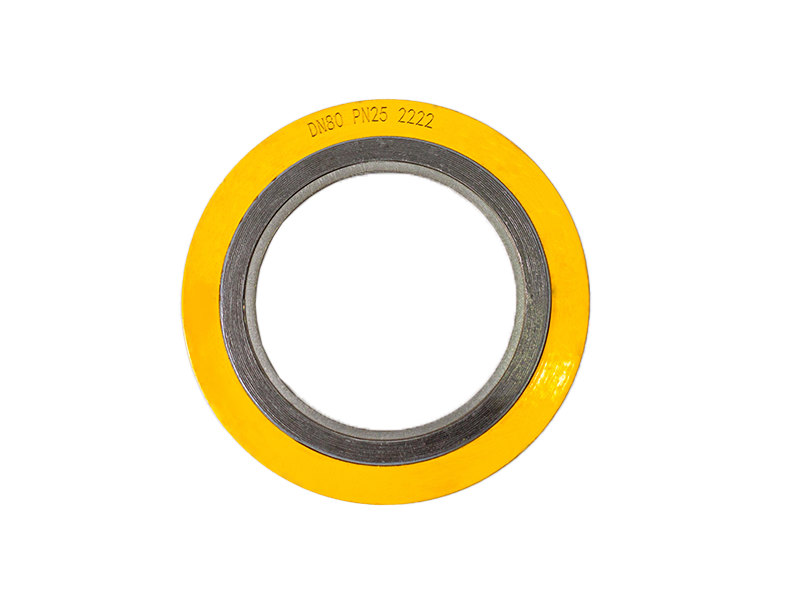

With inner and outer ring type (with inner ring and middle ring type) |

|

Section shape |

|

|

|

Applicable flange sealing surface form |

|

Convex (also applies to full screen) |

Performance parameters

| Identification code | Temperature (℃) | Applicable media | Compression rate% | Rebound rate% | Stress relaxation rate (%) |

| HS8512 | -200~650 (for oxidation medium maximum temperature 450 ℃) | Corrosive medium | 18-30 | ≥ 17 | ≤ 18 |

Product Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend Products