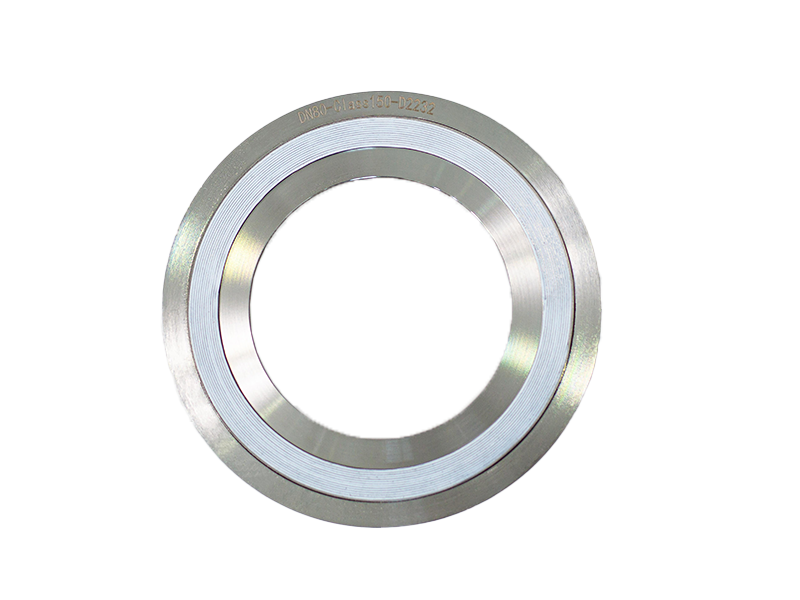

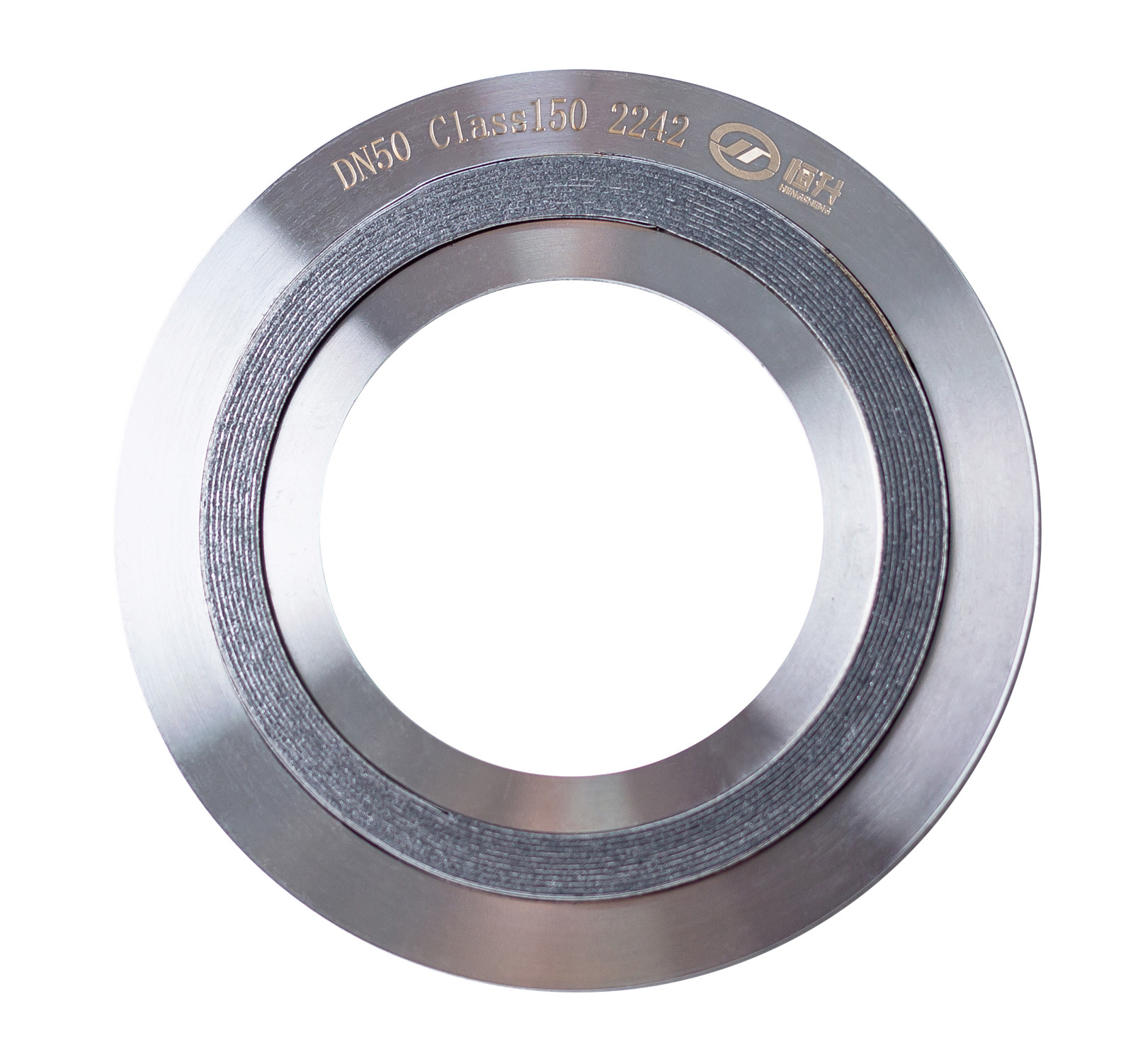

HS8513 PTFE wound gasket

Categorie:

Tags:

Product Introduction

HS8513 PTFE metal wound gasket is formed by alternately winding thin steel strips and PTFE strips. Its structural density can be made according to different locking force requirements. It uses inner and outer steel rings to control its maximum compression. It has the advantages of good resilience, corrosion resistance and low leakage rate. In the gasket category, it is most suitable for sealing at corrosion resistance and vacuum parts. Valves, pumps, heat exchangers, towers, manholes, hand holes and other flange joint static sealing components. Widely used in petrochemical, machinery, electric power, metallurgy, shipbuilding, medicine, atomic energy and aerospace and other fields.

,

,

Performance parameters

| Identification code |

Temperature |

Pressure (Mpa) |

Applicable media |

Compression rate% |

rebound rate |

Stress relaxation rate (%) |

|||

| A | B | C | D | ||||||

| HS8513 |

-200~ 260 |

Corrosive medium |

18-30 |

≥ 15 |

≤ 13 |

||||

Product Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend Products