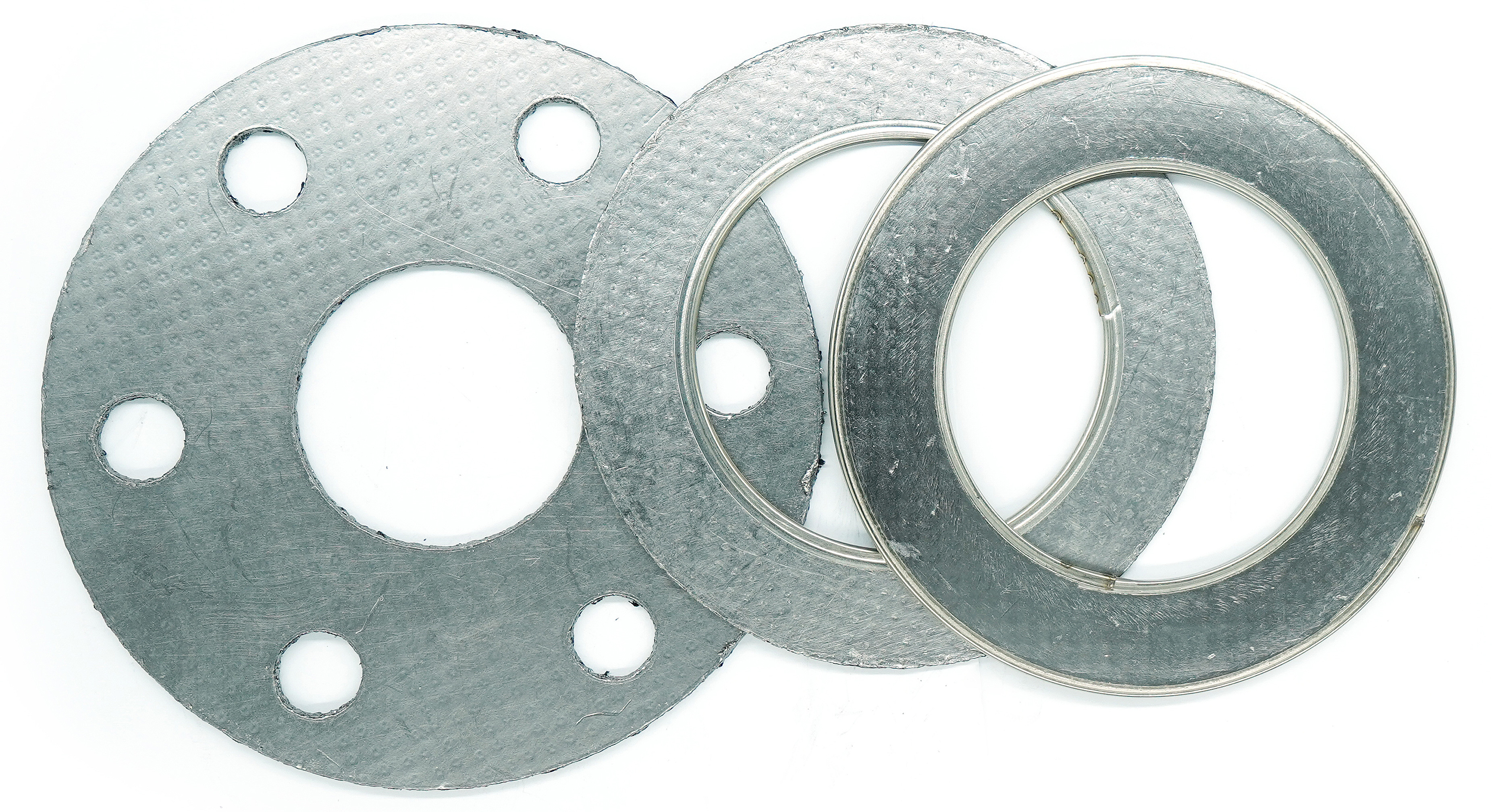

HS856 Flexible Graphite Composite Gasket

Categorie:

Tags:

Prev:

:Next

Product Introduction

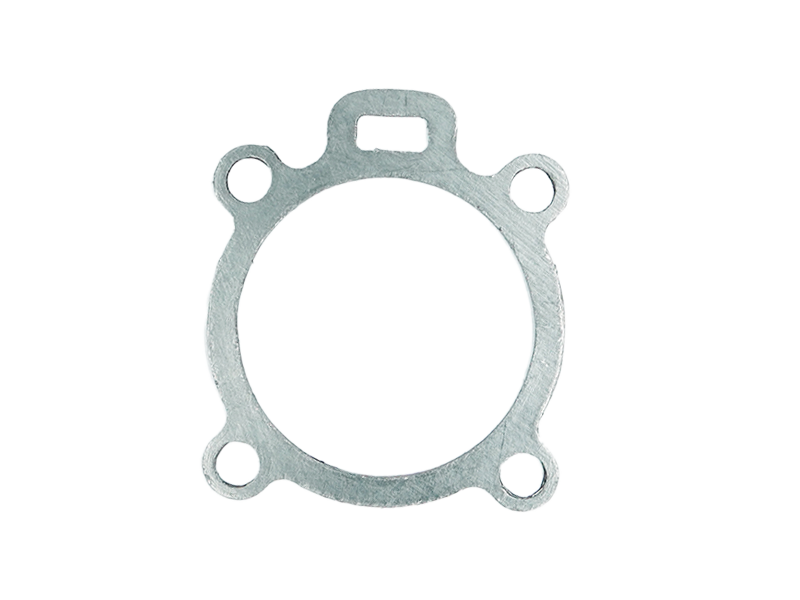

Flexible graphite composite gasket is an improved semi-metal gasket, which is formed by punching or shearing a high-strength graphite sheet composed of a metal sprint plate and expanded graphite particles. It has excellent corrosion resistance, high and low temperature resistance, good compression resilience, and good strength. It is a good original for sealing pipelines, valves, pumps, pressure vessels, heat exchangers, condensers and other equipment. It can also be cut into complex shapes. Gaskets, such as water level gauge gaskets, punched flange gaskets and cylinder gaskets for automobile diesel engines. Can maintain the excellent performance of the original gasket, and easy to install, disassemble, not easy to damage, but also to prevent the erosion of the media on the gasket, improve the pressure. It is the first choice for the connection of flange sealing surface of large diameter pressure vessel

Sealing products.

|

|

Ordinary type |

Heterosexual |

Product Type

| Type | Form of sealing surface |

|

Basic Graphite Composite Gasket |

full plane |

|

Graphite composite gasket on the inner edge of the package |

convex surface |

|

Graphite composite gasket outside the package |

Concave/Convex |

|

Interior and exterior hemming graphite composite gasket |

Tenon/groove surface |

Performance parameters

Performance |

Technical parameters |

Gasket Coefficient |

m=2 |

Use of pressure |

≤ 4MPa |

Use temperature |

-196 ℃-650 ℃ |

Minimum preload specific pressure |

y=3MPa |

Product Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommend Products